Hammond Glider TrimOSaw Model G40B

Category: Shop Procedures, Random ThoughtsDate: 2019-04-20

As luck would have it, I'm now the proud owner of a Hammond Glider TrimOSaw. These saws were manufactured from 1928 until the 1960s. They were made for printshops, where they cut lead and wood type blocks for handset type. The particulars of creating and setting type of the era elude me, but the accuracy and features of this saw do not! It is amazing and will find many uses working with small parts.

](/wp-content/uploads/2019/04/Screenshot-from-2019-04-20-10-16-21.png)

](/wp-content/uploads/2019/04/Screenshot-from-2019-04-20-10-16-21.png)

The saw is a small sliding table saw, with precise calibration and 7" carbide saw blade with a 0.010 inch kerf. As a printer's saw, the micrometer cutoff gauge is calibrated in picas and points. A pica is approximately 1/6 of an inch and a point is 1/12 of a pica. The micrometer gauge has detents at each point and one-half of a point. Doing the math, a half point is 1/6/12/2 = 0.007 inch. Each click on the micrometer gauge knob advances the cutoff stop 0.007 inches. Doing some research on print measurements, I found that pica widths were not completely standardized. I found that the pica layout on this machine resulted in 6.03 picas per inch. For the metrically inclined, on this machine a pica is 4.21 mm, and a half point is 0.176 mm.

Naturally after getting the saw up and running, I wanted to have a look at the accuracy it can achieve. My test was to trim a block to a width of 4 inches. 6.03*4 = 24.12 or 24 picas and 1.44 points. I set the guage to 24 picas and turned the dial another 1.5 points. The result was fantastic: a block that measured 4.002 inches. I don't know if you can get excited about that, but I can.

Pianos have lots of small wooden parts, and this saw will be at home in the shop. My recent post about trimming knuckles showed the process on the Delta Unisaw. I had in mind to do it on this saw, but I didn't quite have it up and running when it was time to trim the knuckles.

I bought the saw from a printshop in Ogden a few weeks ago. My intuition and a few internet clues suggest that the saw was made in the 1950s. I replaced the old three phase motor with a new 1 HP single phase motor. I was able to acquire a new blade for the saw, made to Hammond specifications, by The Blade Manufacturing Company of Columbus Ohio. Also included in the purchase but not pictured here is the very nice work hold-down clamp which is designed to hold very small pieces with clamping pressure very near to the blade.

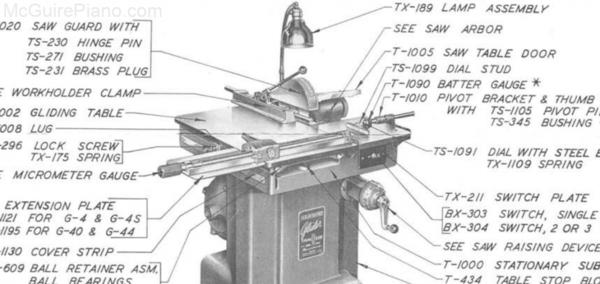

Here's the owner's manual borrowed from vintagemachinery.org: Hammond Glider Saw User's Manual. I love the drawings, knowing that they were all done by hand. Another lost art.

Commments

I welcome your comments. You do NOT need to sign in to leave a comment, but if you create an account and sign in, my comment system will notify you of replies to your comment. Thanks for stopping by.--Duane McGuire